J1939 | Icp Das

The following is an excerpt fromA Comprehensible Guide To J1939 by Wilfried Voss. The other involves standardized parameter groups specified by SAE J1939 featuring a.

Sae J1939 The Ultimate Guide 2021 Autopi

Any J1939 user space library operating on CAN raw sockets will still operate.

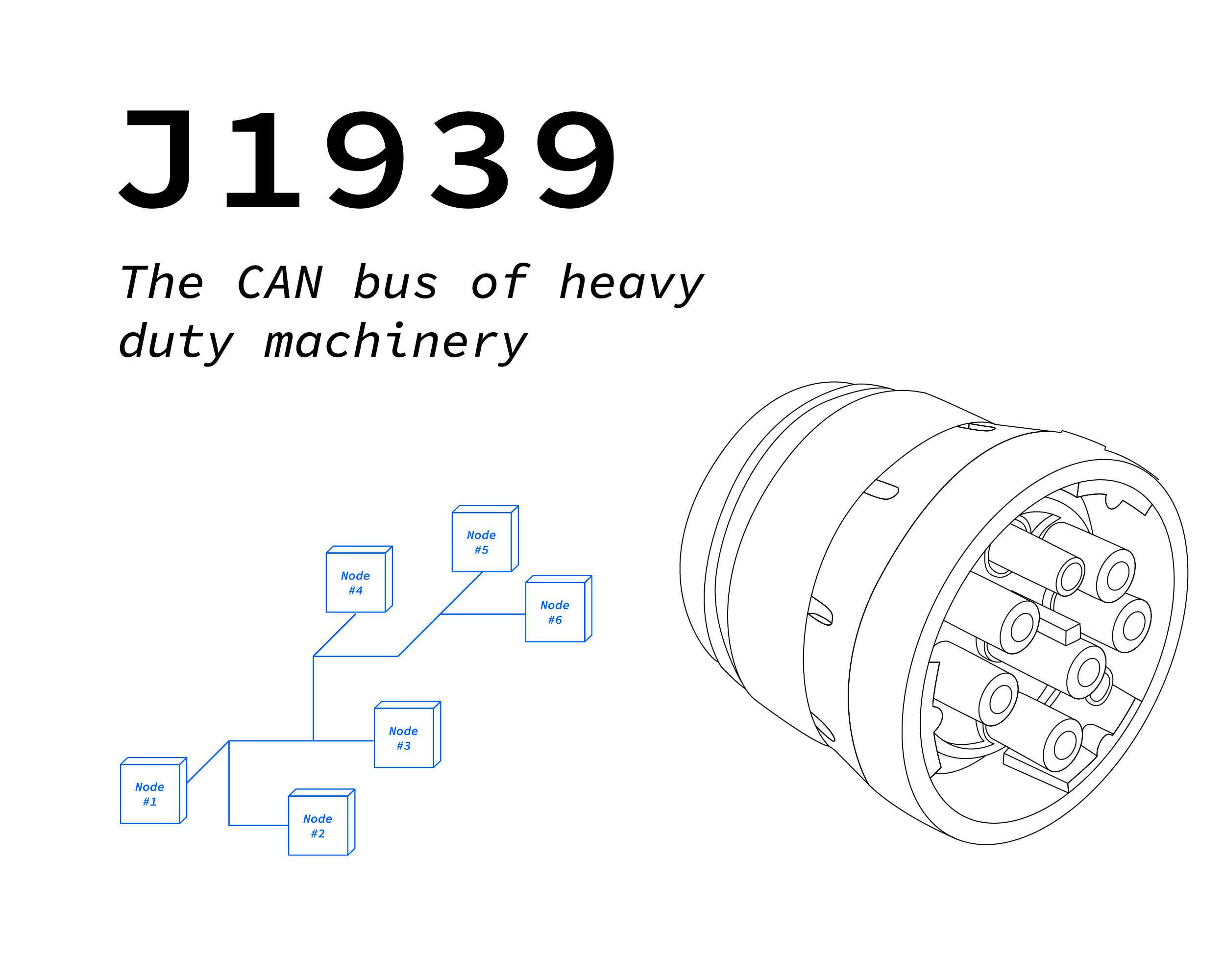

J1939. The J1939 sockets operate on CAN network devices see SocketCAN. Transfer rate is 250 kbps and maximum 30 nodes can be connected on the bus. Introduction to J1939 2 Application Note AN-ION-1-3100 10 Overview SAE J1939 is used in the commercial vehicle area for communication in the commercial vehicle.

It may sound obvious but in order to establish a network you need at least two nodes and that. SAE J1939 uses CAN Controller Area Network ISO11998 as physical layer. The J1939 sockets operate on CAN network devices see SocketCAN.

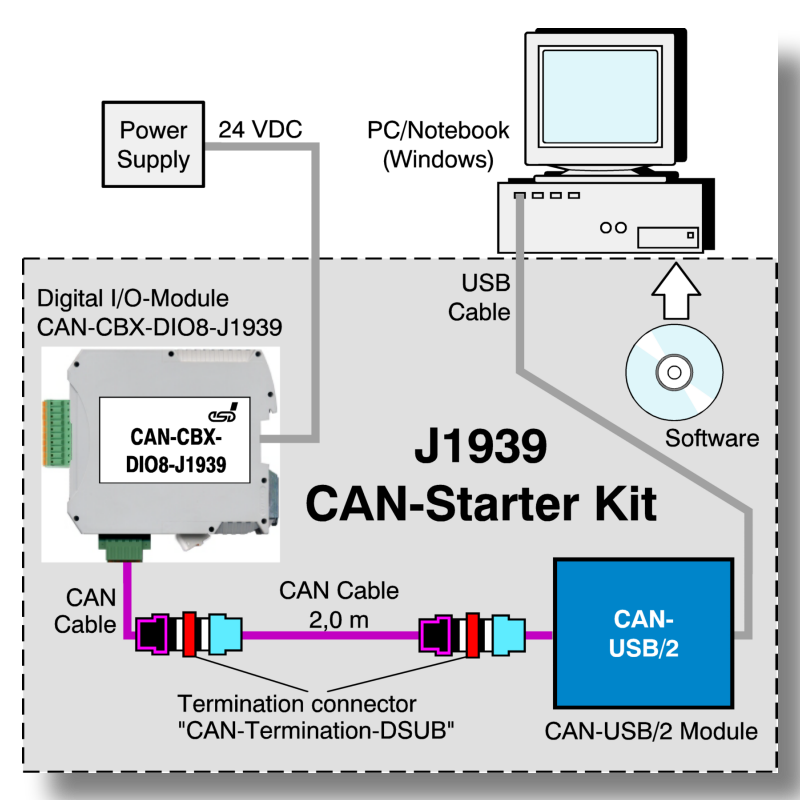

In parallel OEMs will increasingly shift from Classical CAN to CAN FD as part of the transition to J1939 with flexible data-rateIn turn this will increase the need for J1939 FD data loggers. Our JCOMJ1939 Starter Kit And Network Simulator is designed to allow the experienced engineer as well as the beginner to experiment with SAE J1939 data communication without the need of connecting to a real-world J1939 network ie. It is a standard maintained by the Society of Automotive Engineers SAE The standard defines how information is transferred across a network to allow ECUs ie.

With the rise of heavy-duty telematics J1939 will increasingly play a role in the market for connected vehiclesIn turn this will increase the need for secure J1939 IoT loggers. One is the SAE J1939-76 standard which describes a general process for protecting a desired parameter group. J1939 stack is an embedded software stack with layered architecture compliant with SAE J1939 standard.

It is a recommended. SAE J1939 is a standardized protocol that operates in CAN Controller Area Network bus networks. The JCOMJ1939 Starter Kit And Network Simulator is designed to allow the experienced engineer as well as the beginner to experiment with SAE J1939 data communication without the need of connecting to a real-world J1939 network ie a diesel engine.

In-kernel code for these would not contribute to protocol stability. J193921 defines the use of the CAN data frame 29-bit identifier Parameter Group Numbers PGN etc and the transport protocol functions ie. It originates from the international Society of Automotive Engineers SAE and operates on the physical layer with high-speed CAN per ISO 11898.

SAE J1939 protocol is based on CAN ISO 11998-1 and ISO 11998-2. Therefore these parts are left to user space. Vehicle speed Think of J1939 as a software specification that rides on.

J1939 defines some other features relaying gateway fast packet transport. SAE J193911 defines a high speed CAN bus as per ISO 11898. There are 4 specifications defined by SAE J1939.

Reduced Physical Layer 250K bitssec Un-Shielded Twisted Pair UTP J1939-21. Application Layer - Diagnostics. Computers to communicate information.

Application Layer - Generator Sets. Connect and Monitor J1939 Engines. SAE J1939 includes two different approaches for transferring safety-critical data.

For specific examples of modules on each different data link Click Here 2The different J1939 data links work the same way but the wiring for them is not connected. J1939 defines some other features relaying gateway fast packet transport. Aceinna J1939 Protocol AJP is a communication mechanism used for resolution of the identification of CAN nodes configuration and data exchange based upon SAE J1939 and the related standards.

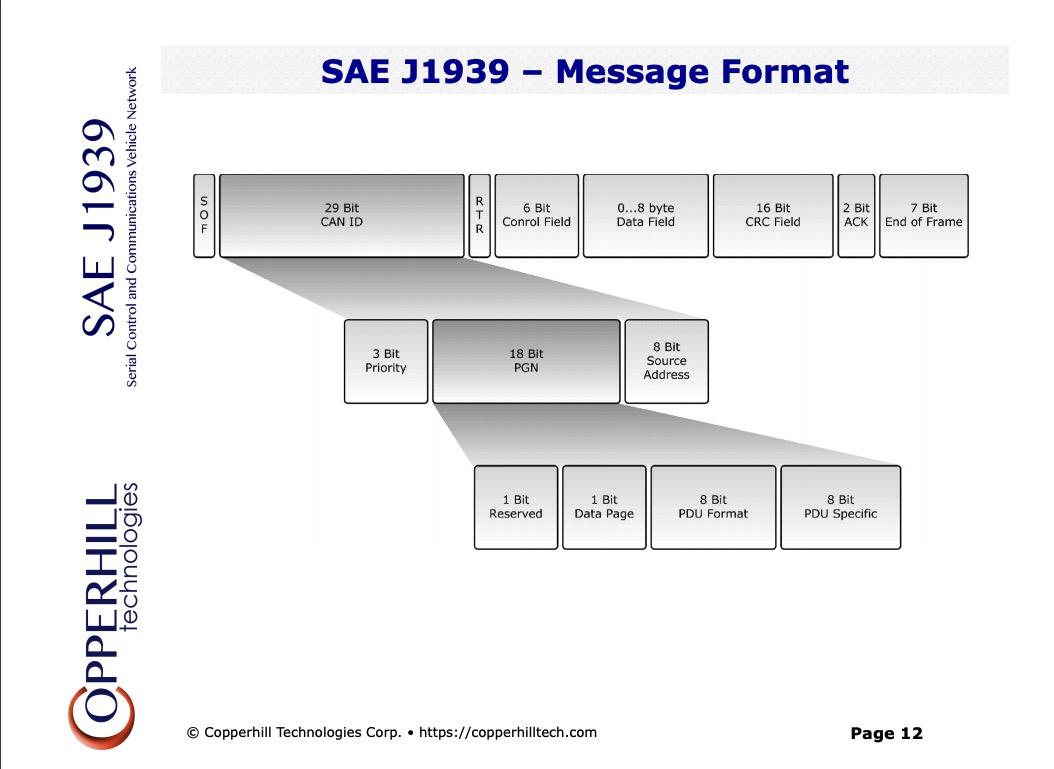

This pre-tested software stack designed by our embedded automotive engineers can be easily integrated with commercial vehicle applications for diagnostics and communication services. The main document describing the J1939 message format is SAE J193921 Data Link Layer. A definition of how messages longer than the standard CAN data.

While other higher layer protocols based on Controller Area Network CAN do not support dynamic node address assignments per default the SAE J1939 standard provides this ingeniously designed feature to uniquely identify ECUs and their primary function. In this application note the properties of SAE J1939 should be described in brief. Network Management under J1939 is primarily represented by the Address Claiming Process.

1First the drivetrain J1939 data link J1939 body builder data link and J1939 engine data link are three completely separate data links. It is a request and reply protocol and communicated within the boundaries of a single CAN networknever routed internetwork nodes. Any J1939 user space library operating on CAN raw sockets will still operate.

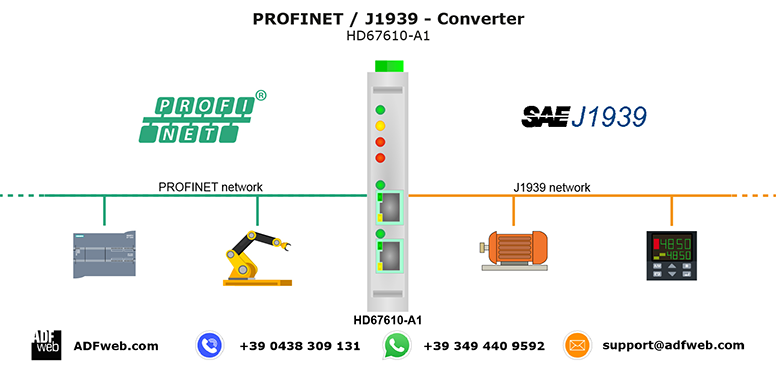

In-kernel code for these would not contribute to protocol stability. J1939 is a multimaster system with decentralized. SAE J1939 is a communication protocol based on CAN for real-time data exchange between control units in the area of commercial vehicles.

SAE J1939 Starter Kit And Network Simulator. It is widely used in industrial diesel engines designed for the heavy-duty vehicle industry including on-highway trucks off-highway equipment agricultural equipment construction equipment and other vehicles. SAE J1939 Starter Kit And Network Simulator.

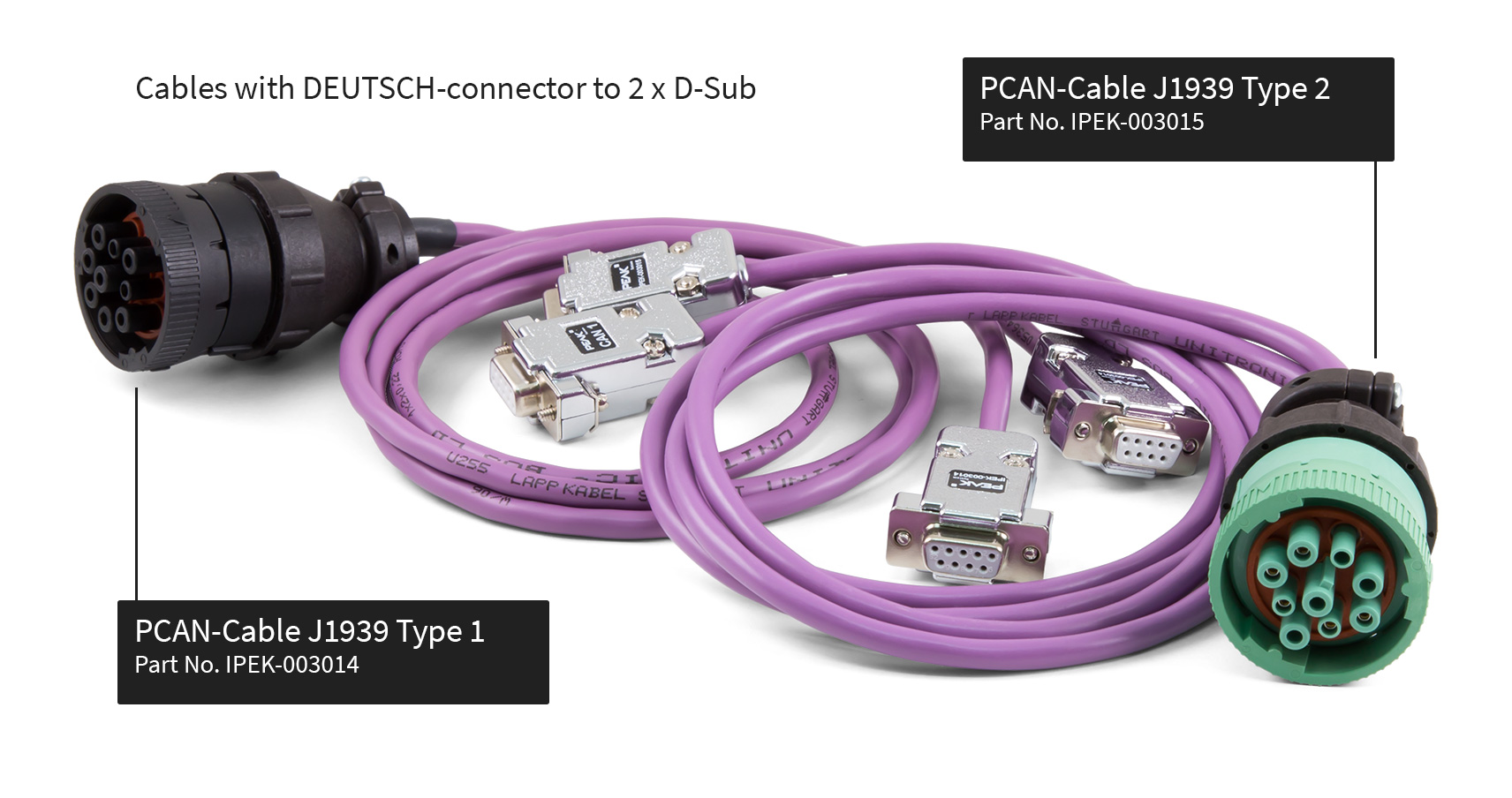

This includes shielded twisted pair cable and ground. Therefore these parts are left to user space. Application - Configurable Messaging.

Sae J1939 Message Format And Interpretation Of Pgns Copperhill

Can Data Frame As Defined By J1939 8 Download Scientific Diagram

J1939 Explained A Simple Intro 2021 Css Electronics

Datei J1939 Aufsplittung Can Identifier Png Wikipedia

Produkte Und Entwicklungsdienstleistungen Fur Sae J1939

Sae J1939 Diagnose Leicht Gemacht Gemac Chemnitz Gmbh

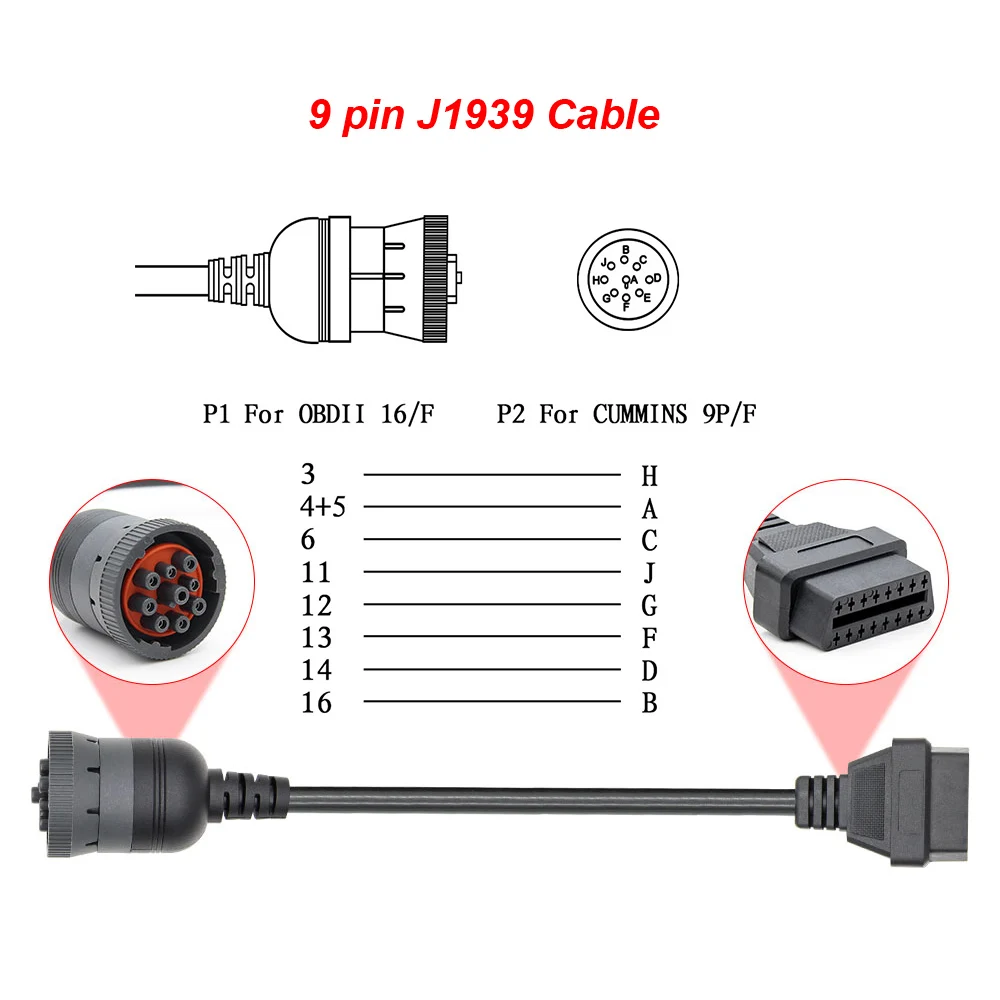

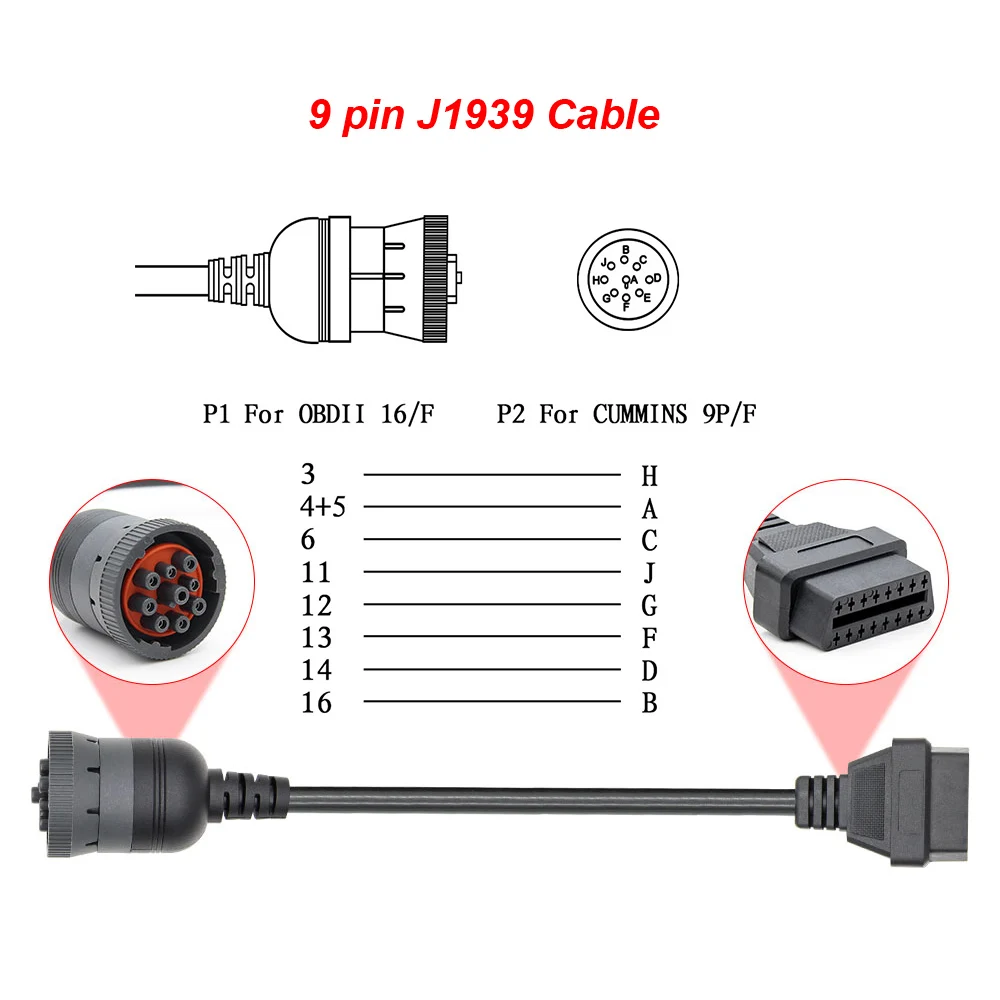

Hot Sale Obd2 Truck Diagnostic Tool 16 Pin Cable J1708 J1939 Connector Obd To Obd2 6 Pin 9 Pin Truck Cable For Cummins Truck Car Diagnostic Cables Connectors Aliexpress

.png)

Ahd J1939 Datensteckverbinder Fur Fahrzeuge Amphenol Sine Systems Mouser